Type:

Specification:

MBB Solar Cell Stringer Machine is to weld the solar cells one by one through copper ribbon, and the cells are connected in series to form a string. The entire welding process is fully automated.

|

No. |

Basic parameter |

Value |

|

1 |

Cell dimensions |

156x156-220x220mm |

|

2 |

Cell thickness

|

0.15-0.2mm |

|

3 |

Busbar quantity |

5BB-12BB |

|

4 |

Cell gap |

0-25mm |

|

5 |

Max. string length |

2500mm |

|

6 |

Ribbon |

Flat ribbon, round ribbon, triangular heterogeneous ribbon (customized) |

|

7 |

Flux spraying method |

Ribbon immersion & heating |

|

8 |

Soldering Method |

Infrared heating(PID control) |

|

9 |

Breakage rate |

≤ 0.15% |

|

10 |

Max. capacity |

3600 pcs/h(half cell), 4400 pcs/h(one third cell) |

|

11 |

Dimension |

7200x2080x2300mm |

|

12 |

Stringer weight |

7000KG |

|

13 |

Average power |

20KW |

|

14 |

Input voltage |

AC380V, three-phase, 50HZ |

|

15 |

Input compressed air pressure |

6-7bar |

|

16 |

Input compressed air flow |

800L/min |

Ooitech, One-stop Solution For solar module manufacturing machine.

Has The Following Required Machinery And Accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assitance, Solar Power Station installation technical support Etc.

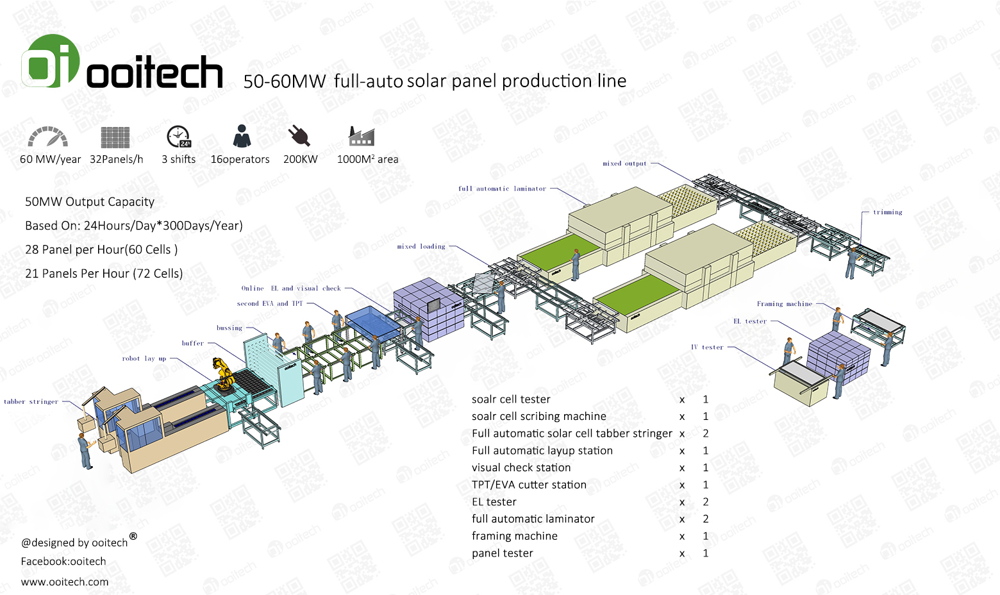

Supply 10MW-500MW solar module manufacturing machine

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine 2022 Solar Cell Laser Scribing Machine With Auto Devide

2022 Solar Cell Laser Scribing Machine With Auto Devide Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H

Solar Cell Non-Destructive Laser Scribing Machine 3600 PCS/H 6000PCS/H 2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line

2345 Double Chamber Fully Automatic Solar Panel Laminating Machine of Solar Panel Production Line  Solar Panel EL Defect Tester with Visual Inspecting - Solar Panel Production Line

Solar Panel EL Defect Tester with Visual Inspecting - Solar Panel Production Line Solar Module Gluing and Framing Machine - Solar Manufacturing Machine

Solar Module Gluing and Framing Machine - Solar Manufacturing MachineBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)