Type:

Specification:

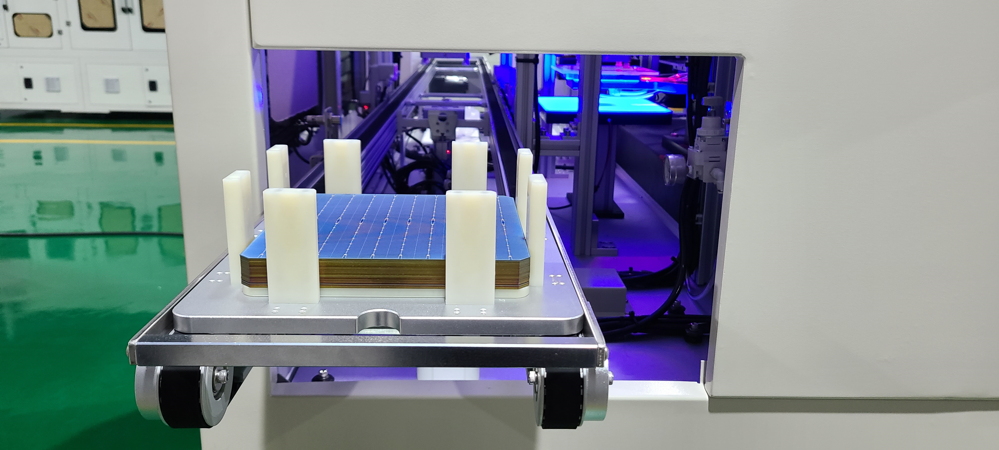

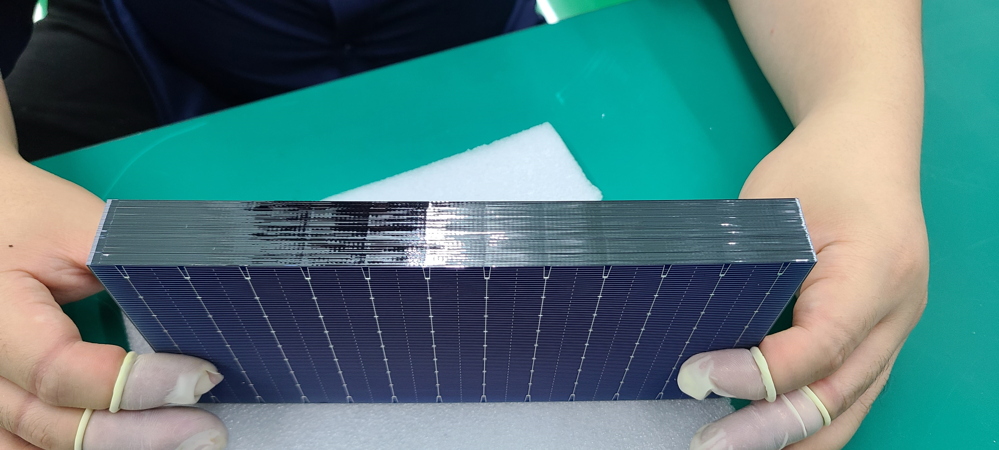

Solar Cell Non-Destructive Laser Cutting Machine cuts solar cell into half piece or 1/3 piece,which can increase the output of the solar panel power.

|

Classify |

Item |

Technical index |

Remarks |

|

|

Equipment performance |

Applicable solar cells |

Cell Type |

Bifacial Mono Solar size:156-220mm Half Cut |

reserve the space to update 1/3 1/4 ; less than half hour to switch different sizes solar cells |

|

Cell thickness |

100-200μm |

Maximum thickness deviation of one batch of cells <20μm |

||

|

Cell Grid line layout |

The cutting area of both the front or back side of the cells, must have blank area with width ≥1.5mm (no thick or thin silver grid line) |

|||

|

Cell warpage |

<2mm |

A, B grade cell |

||

|

Maximum capacity (SL5-UD3600) |

3600pcs/h (full cell) |

calculate as 166 perc solar cell |

||

|

Maximum capacity (SL5-UD7000) |

7000pcs/h (full cell) |

|||

|

Equipment utilization |

≥99% |

failure rate ≤1% |

||

|

Fragmentation rate |

≤0.05% |

Including fragments, missing corners, chipped edges and other poor appearance |

||

|

Equipment operation |

Touch screen + regular operation buttons + external wireless keyboard and mouse |

|||

|

Process index |

Heat affected zone |

No |

||

|

Comprehensive cutting accuracy |

Centering accuracy ±0.05mm |

|||

|

Laser index |

Slotting laser |

50W |

SPI/IPG |

|

|

Splitting laser |

200W |

Behring (Delphilaser own brand) |

||

|

Laser wavelength |

1064nm |

|||

|

cooling method |

Natural cooling |

|||

|

Laser lifetime |

30,000 hours |

|||

|

Laser protection |

Level 4 safety protection |

Safety light curtains + optical sealed box +Safety door+ Protective glasses |

||

|

Camera |

Camera |

High resolution industrial camera |

20 million pixels, positioning accuracy ≤±0.05mm |

|

|

Camera light source |

Upper light source + lower backlight |

|||

|

Loading detect |

Detect the cell chipped edge corner chip |

Take away NG cells |

||

|

Unloading detect optional |

The chipped edges , corner chip, offset of cutting line |

|||

|

Automatic process |

automatic loading |

Manipulator |

8 feeding boxes, 120 Cells/ boxes |

|

|

Automatic unloading |

Belt + manipulator |

Standard unloading box |

||

|

Splitting ways |

Laser |

Automatic split |

||

|

upgrade |

MES window |

Reserve MES window |

Support multiple data output |

|

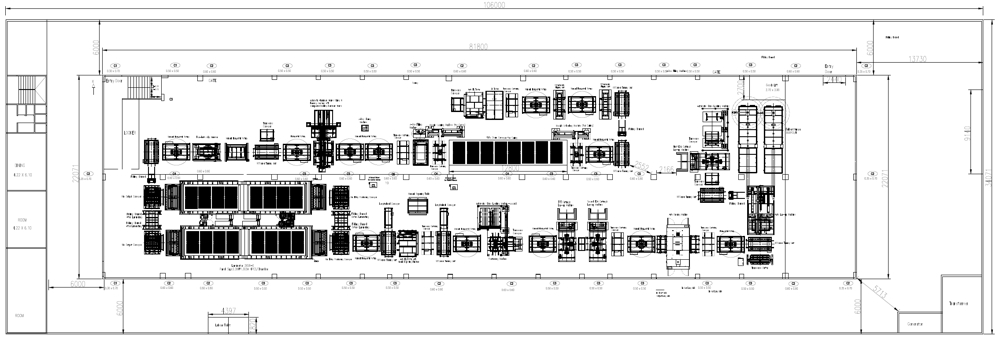

Ooitech, One-stop solution for solar module making machine. Has the following required machinery and accessories

Ooitech “Turnkey Solution” Includes: Factory Construction, Facility Layout, Raw Materials BOM guidance, Production Procedure assistance, Solar Power Station installation technical support Etc.

Supply 10MW-500MW Solar Module Making Machine

Update the traditional PV line to newest MBB solar panel production line.

Solar Cell Tabber Stringer Machine

Automatic Solder Bussing Machine

Tabber and Stringer Machine - MBB Solar Cell Stringer

Tabber and Stringer Machine - MBB Solar Cell Stringer Solar Stringer Layup Machine - Solar Panel Production Line

Solar Stringer Layup Machine - Solar Panel Production Line High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H

High Speed Fiber Laser Cutting Machine For Solar Cell - 158 210 4000 PCS/H  2022 Solar Cell Laser Scribing Machine With Auto Devide

2022 Solar Cell Laser Scribing Machine With Auto Devide 156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine

156-210 Mbb 50-60s/Panel Auto Solar Cell String Bussing Machine Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/H

Tabber Stringer Machine - MBB Full Automatic Solar Cell Stringer Machine 3600PCS/HBuilding 1, Zixin Industrial Park, Yangguang Ave,Jiangxia Economic Development Zone, Wuhan of China

Mon-Fri: 8.30AM-5.30PM (UTC+8)